The Effect of Hob Mounting Errors

2022-01-13 11:02:32

jiangxingTools

2826

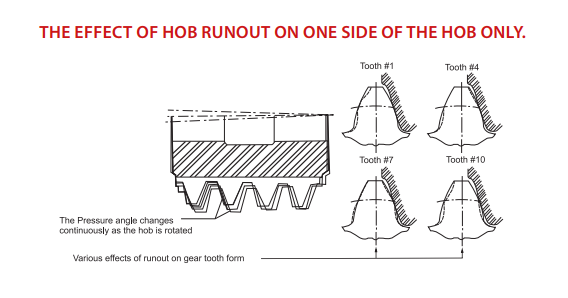

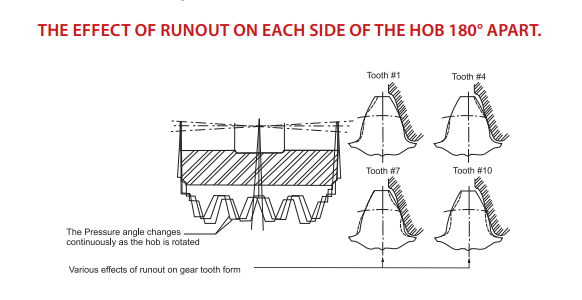

The Effect of Hob Mounting Errors

Despite hypothetically perfect hob, manufactured error free, the hob can produce profile errors if mounted eccentrically on the hobbing machine arbor. Hob runout error due to either careless mounting or to improper resharpening is the greatest contributor to out-of-tolerance hobbed involute profiles. Figures 1,2, & 3 illustrate the effects three types of hob runout have upon the gear tooth form. These effects are created, most often, by:

Failure to true up the hob arbor.

Failure to true up the hob on the hob arbor by truing the hub indicating bands.

Bent, oversize or undersize hob arbor.

Non-parallel hob clamping spacers, misaligned or wornout arbor support bearing.

相關文章